The Challenge

Automotive door quality, especially in the areas of wind noise and water leakage is a perennial JD Power customer complaint. With the advent of infotainment systems and hands free-calling, it is of utmost importance to design and produce cars that exceed expectations in these categories. The quietness of electric vehicles necessitates elimination of wind noise now more than ever.

In the past, hidden and hard to reach/see gaps were often measured with manual, tedious or clumsy methods such as feeler gauges, friction blocks or even clay/calipers. A global automotive OEM came to Inora looking for a faster, highly accurate, digital, wireless, temperature stable system to measure hidden seal gap in car doors. This prompted the creation of the WiseGap system.

WiseGap was developed using OI Core Technology to meet and exceed the challenge of replacing manual and numerically uncertain digital methods of gap measurement. It was designed to be universally applicable across all closure types and for steel as well as non-magnetic car bodies.

WiseGap software features OI Core Technology to provide numerically certain user calibration of the system at any time. The supporting hardware is very precise and can be adapted to a number of applications within automotive and beyond to other industries, such as heavy industry, appliances and aerospace to name a few.

Our

Solution

Applications Of Wireless Gap Measurement

From various industries, to different applications within them, WiseGap is a very flexible tool for gap measurement and dimensional validation. Here are some selected examples:

Automotive Design, Research & Development

High Frequency Measurement

System Is Flexible To Adapt To Various Models

Automotive Production And Quality Control

Static Measurements And Specialized Reporting For BIW

Live Adjustment To Resolve NG Closures In QA/QC/Trim

Heavy Industry

Check Gap/Evenness Between Stamping Press

Check Roller Gaps

Appliances

Temperature Invariant Sensors to Check Gaps In Fridge/Oven

Custom Adapters To Measure Various Appliance Gaps

WiseGap Benefits

WiseGap Is Powered By OI Core Technology Supported By Precision Hardware

Identify And Resolve Launch Issues

Diagnose And Eliminate Poor Closure Fit That Causes Automotive Wind Noise / Water Leakage

Improved Customer Satisfaction

Perennial JD Power Top Customer Complaints Include Door Closing Effort (Affected By Fit) And Wind Noise – Avoid And Mitigate These Issues With Proper Closure Fit Powered By WiseGap

Improve Quality Control

Understand Root Cause of Closure Geometry Issues & Make Process Adjustments When Applied Throughout Production Line (Body in White, Paint, Final QC)

Temperature Invariant Precision

Absolute Numerical Accuracy Powered By Inora’s Core Technology – Sensor Design Is Temperature Compensating To Eliminate Effects From Hot Or Cold Environments

Customer Success Stories

Premium European Automotive OEM Implementation Of WiseGap As A Global Standard For Closure Control

While most global automotive OEM’s utilize WiseGap to some degree in their operations, one premium European brand has been unique however, making the WiseGap a global standard at multiple points in their process:

- Research And Development

- Measurement In Body Shop

- Measurement After Paint Shop

- Measurement After Trim Ship

By implementing WiseGap systematically, the OEM’s internal quality metrics showed a 35% improvement.

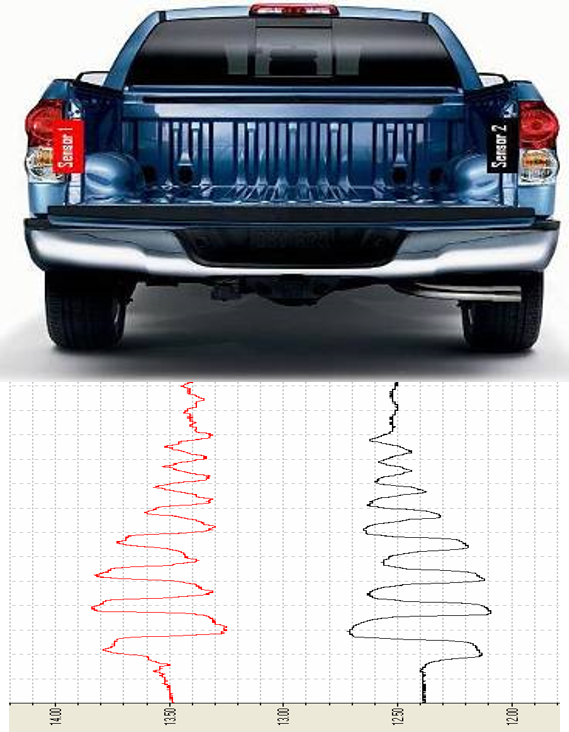

Ability To Better Adjust And Test Closures Dynamically In Vehicle Design And Testing

A Premium Japanese OEM wanted a faster, more accurate way to set their doors in the design phase of a model. While they previously used clay, by implementing WiseGap, they were able to have quick digital feedback in real-time in order to set and adjust their closures.

Once the closures had been set properly, the WiseGap also helped to monitor and understand closure behavior on test drives and wind tunnels to optimize closure behavior. This ultimately saved time and improved closure design/execution.