The Challenge

Traditionally, there was no holistic way to check 3D equipment, whether CNC machines or metrology equipment such as a CMM. Everything was done using hardware centric methods that are heavily dependent on operator knowledge/skill and also rely on estimations, assumptions, alignments (physical and/or mathematical) and approximations. This ultimately produces uncertain results to understand a machine’s true capability.

Over the years a number of tools have been developed to try and address the task of machine verification. When these methods were developed, they remained hardware centric. If they offered any software/analysis capabilities they were bound to the operator’s skill and assumption-based analytics.

A few examples include: 1-dimensional ball-bars and “golden parts”. It is common opinion that these traditional tools get results that are “good enough” or that simply because a certain level of precision isn’t required in an application that these uncertain checks will suffice. To reframe this idea, the emphasis should not be placed on the level of precision — rather on the level of uncertainty in the results they provide. Additionally, if any assumptions were made to get to those results what errors could slip past them and cause downstream issues? Now, introduce the fact that different methods were used between production CNC and metrology equipment, and the potential gap, conflicts, and issues only widen.

Inora developed a solution using OI Core Technology alongside BAE Systems to provide a universal Machine Check platform for ultimate control. A few further requirements for the check were: numerical certainty, alignment-free, absolute hardware reference, and universal application between production and metrology.

Thus was the InoraSRS (Spatial Reference System) was created in it’s initial form. As InoraSRS software utilizes OI Core Technology, the results are numerically certain and unaffected by any alignments. The software evaluates machine parameters/characteristics in a step-by-step first principle order. For example, if a probe is out of tolerance, further machine parameters will not be displayed until the probe capability is within tolerance. The software can be universally applied to any equipment that can output raw X,Y,Z data.

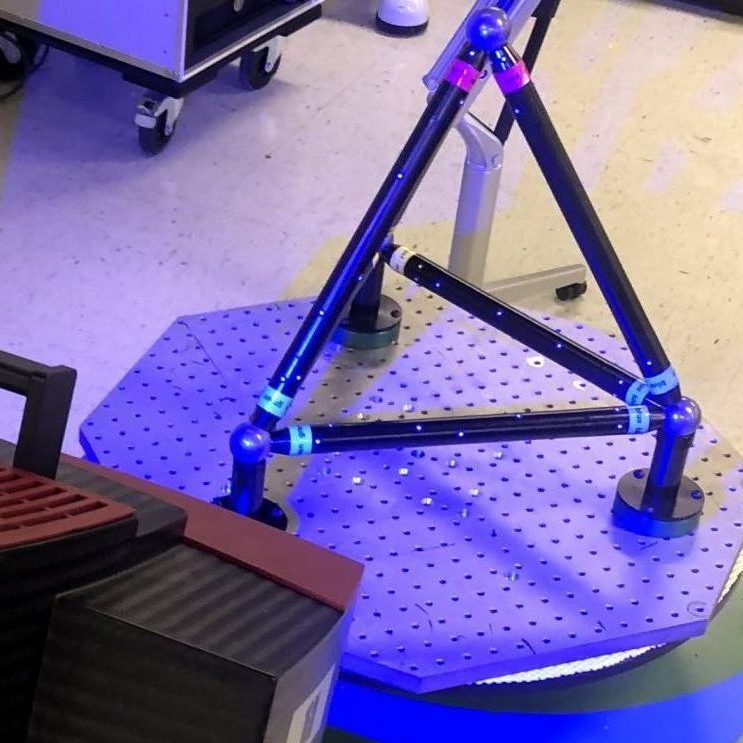

The InoraSRS hardware was designed to be a true tetrahedron (the first platonic solid) for it’s geometric stability. Once this was established, the precision/stability of the hardware was perfected and the climate invariant design was/is patented. This is important as an absolute, climate variant hardware reference is needed to check machine capability when paired with numerically certain software.

Ultimately, InoraSRS provides users with a universal (production and metrology), operator independent, fast way to check machine capability that gives reliable results, is free of false positives / false negatives and can be automated to help avoid scrap/rework, save on calibration costs and put control back in the user’s hands.

Our

Solution

Applications Of Universal Machine Control

From offline inspection to in-process control InoraSRS can be used to verify and monitor the capability of any 3-dimensional system capable of feedback, some examples below.

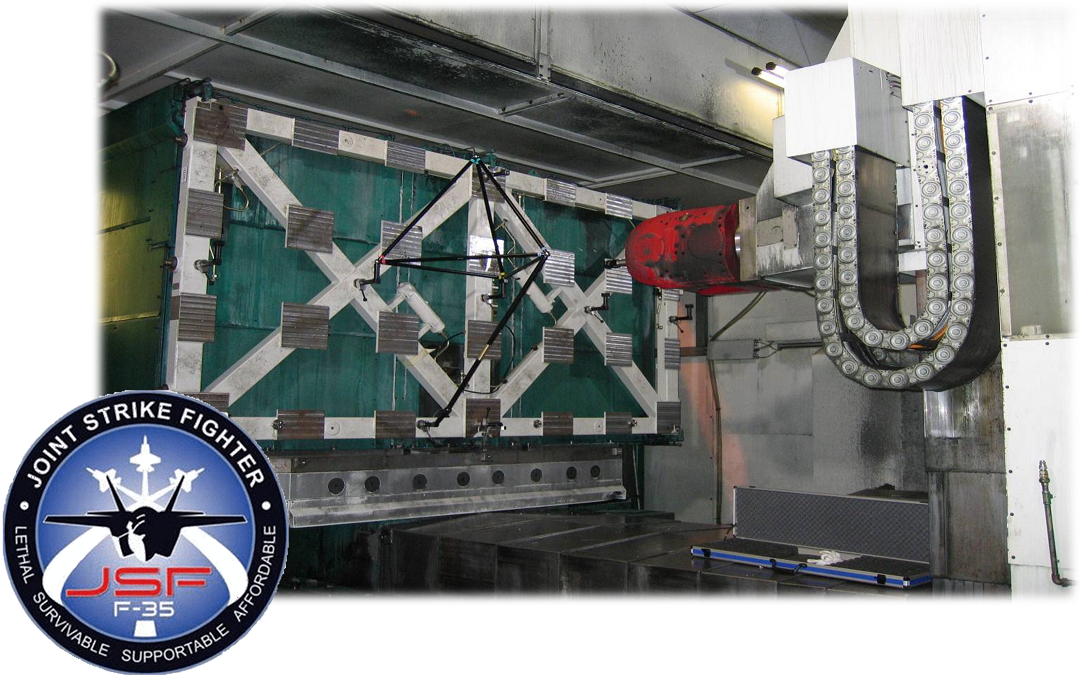

3+ Axis CNC Milling Machine Verification

Check Capability Before Machining Critical/Valuable Parts

InoraSRS Can Be Implemented On Pallet System For Automated Check

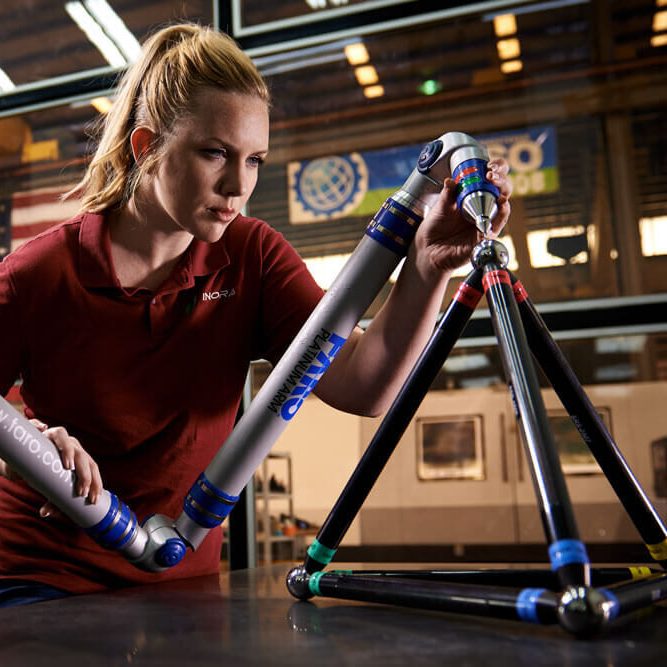

Portable Measurement Arm Verification

Check Any/All Quadrants

Compatible With Tactile And Laser Scanning

Check Before And After Shipping/Transport

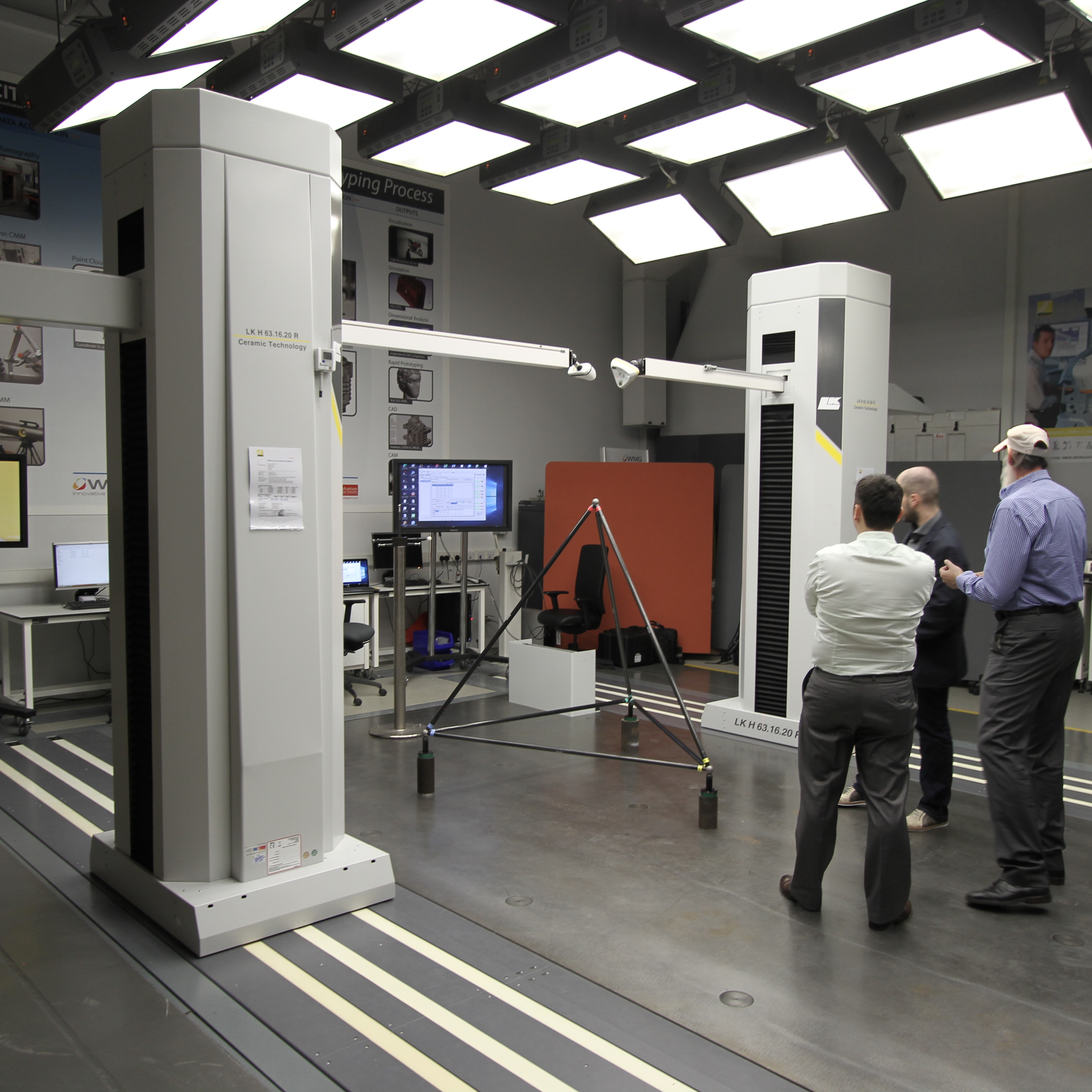

Dual Arm / Twin Column CMM Verification

Check Arms/Columns Independently

Measure With Both Arms To See How Coupling Influences Results

Laser Tracker, Laser Radar Verification

Check At Various Distances

Check Before And After Shipping/Transport

Compare SMR, Probing, And Scanning Results. (Laser Tracker)

Photogrammetry Verification

Test Various Targeting Strategies – Then Apply Best Strategy When Measuring Parts/Product

Check At Various Distances

Compatible With Any 3-D Photogrammetry System (e.g., Blue Light, White Light, etc.)

Gantry / Traditional CMM Verification

Check Entire Envelope Of Machine

Compatible With Touch Probing, Tactile Scan Probing, And Optical Scan Probing

Ability To Test Capability Post-Colision

InoraSRS Benefits

InoraSRS is Software Powered by OI Core Technology With Absolute Supporting Hardware

Baseline your machines

Get a true picture of the real-world capability of your equipment starting at buyoff, or the first time you use the SRS. Monitor machines at regular intervals and quickly asses accuracy after an incident and/or shipping portable equipment.

Scrap, rework, recall prevention

For CNC machining, using SRS before cutting a part can avoid scrap and rework – instantly saving thousands of dollars. In Metrology applications, catching a machine problem before scheduled annual calibration can prevent recalls.

Control your calibration cycles

Calibrations are absolutely necessary when a machine is beyond its acceptable limit, but why not perform them when necessary instead of in fixed intervals?

Isolate Error Sources

SRS identifies error source(s) with numerically certain correction values. No assumptions are made, giving you a reliable diagnosis. Knowing the geometric accuracy of your machine eliminates a variable in the manufacturing process.

Customer Success Stories

Don’t take our word for it – here’s what our clients say:

The InoraSRS Spatial Reference System has revolutionized the Capability Management of our manufacturing processes.

Trevor Smith

Specialist Engineer, BAE Systems

The initial implementation of the InoraSRS led to a 56% reduction in machining errors.

Dr. Mo Omari

Technical Fellow, Manufacturing Technology, General Motors