The Challenge

Historically, evaluating measurement data of geometrical features in manufacturing required physical and/or mathematical alignments. These alignments directly affect the results.

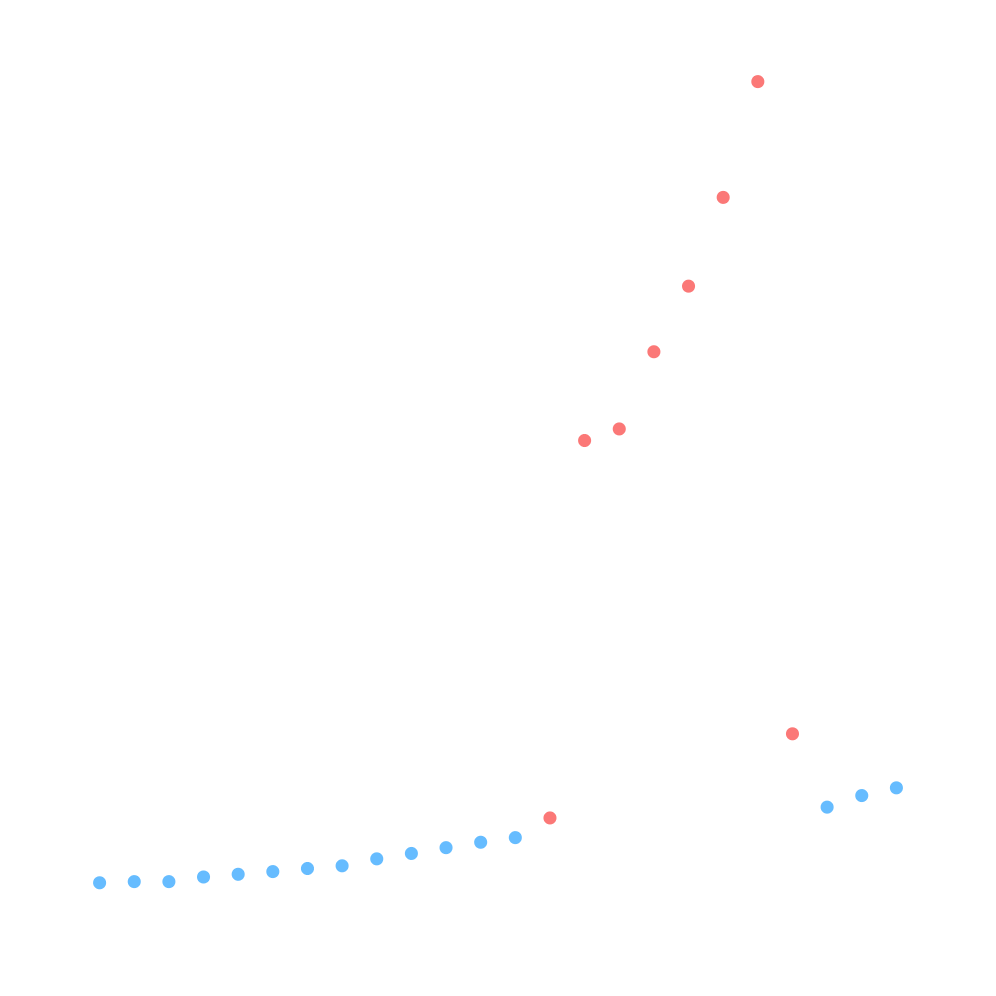

To further complicate matters, the data collected by measurement systems (e.g., scanners, CMM) can contain noise and anomalies. Lastly, real manufactured parts do not realistically represent a perfect mathematical geometry and contain variation and imperfections. Because the alignment itself already introduces error, it becomes impossible to distinguish between measurement system capability, anomalies and part quality.

The final challenge is that using inspection software, there are various manual cleanup methods, filters, and processing layers. This leaves no way to know how far off geometrical results truly are.

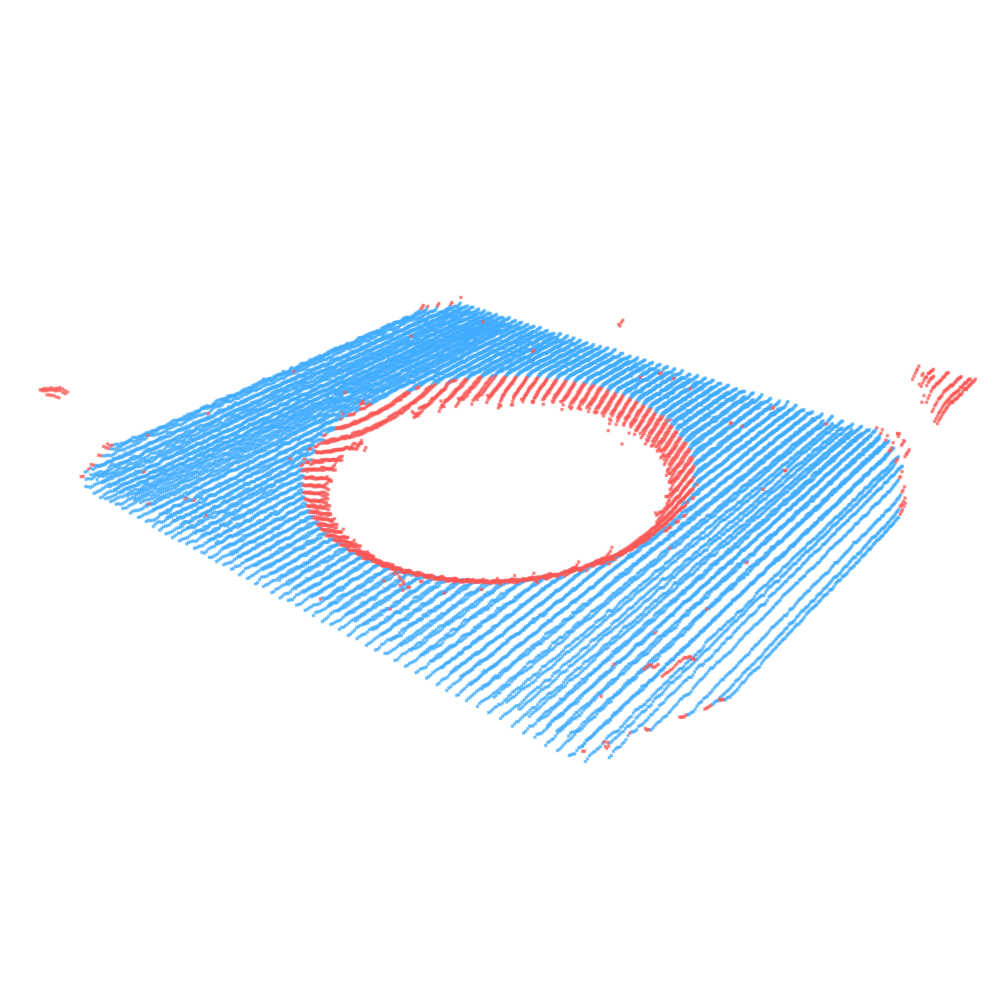

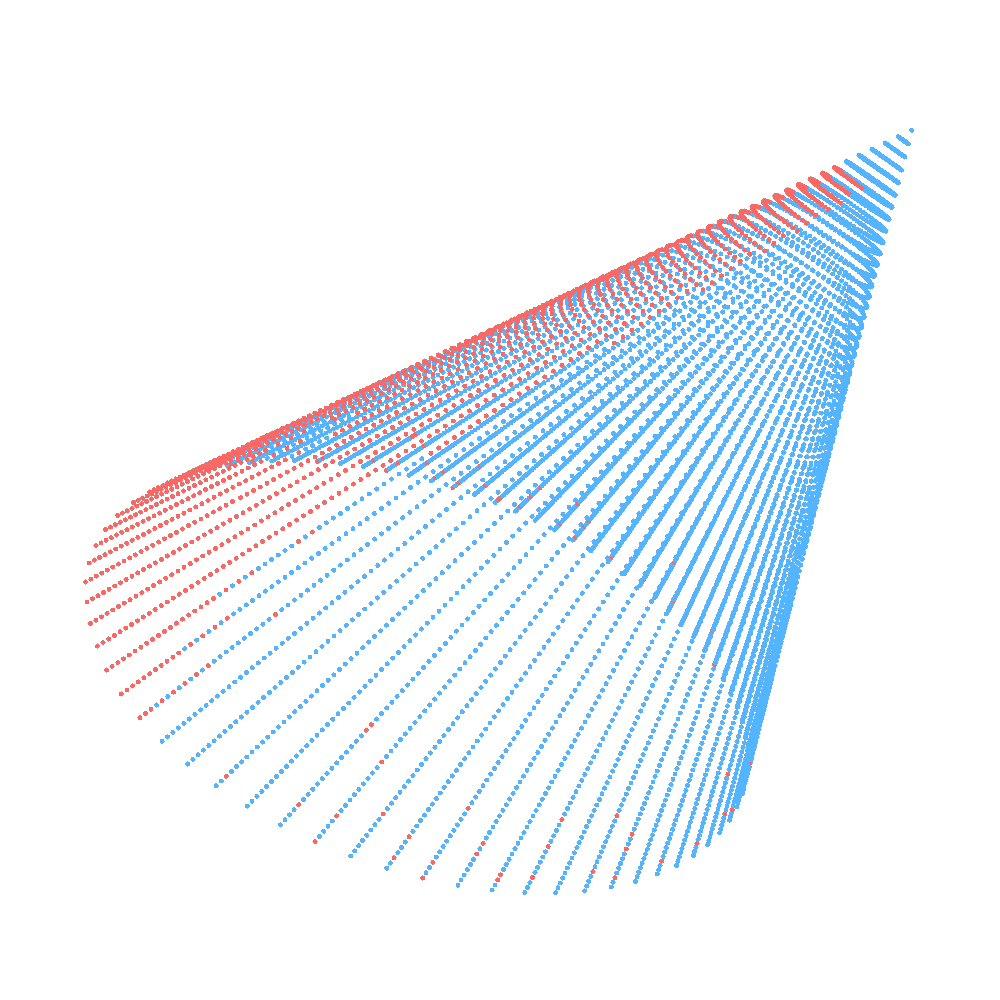

By applying OI Core Technology to geometrical analysis, you instantly gain access to one single, absolute alignment based on the center point and geometric structure of the data.

Inora has applied OI Core Technology to a wide array of geometrical functional models. A list of currently available OI powered software modules is shown below. Further geometrical/dimensional functions can be developed by request.

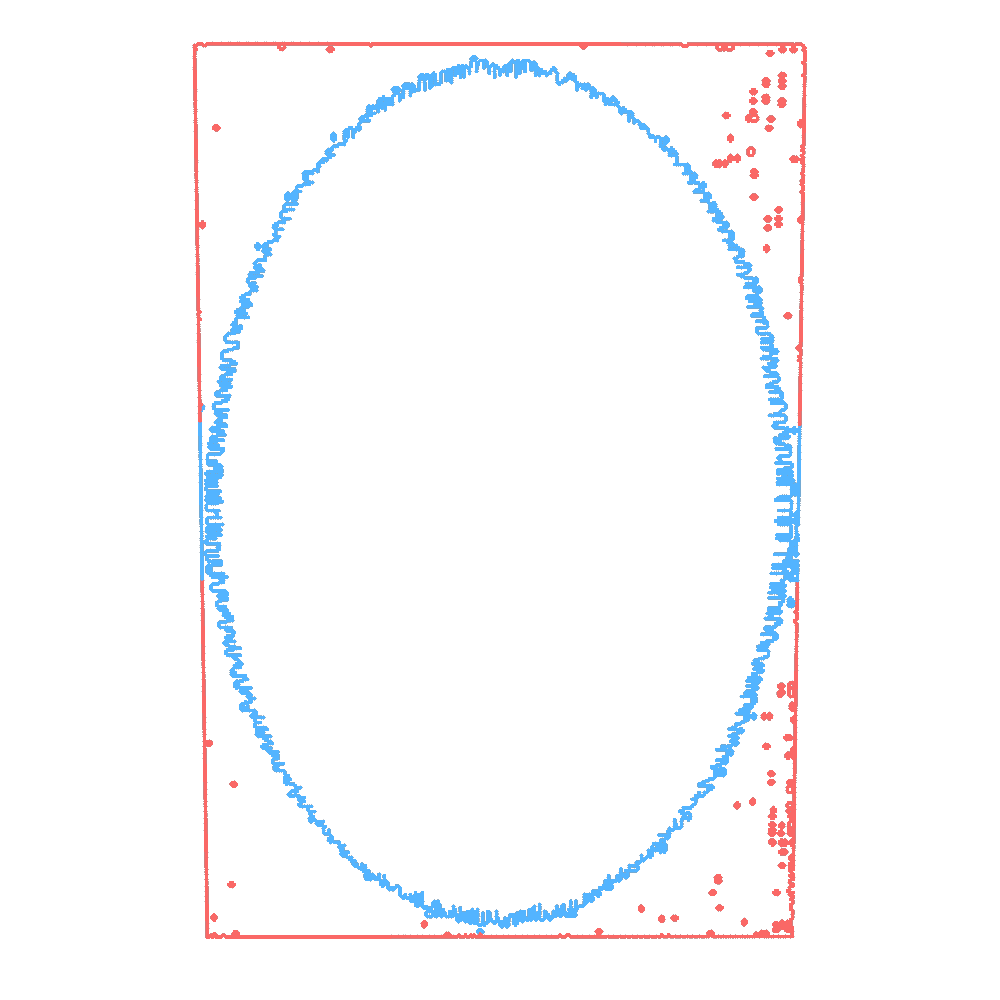

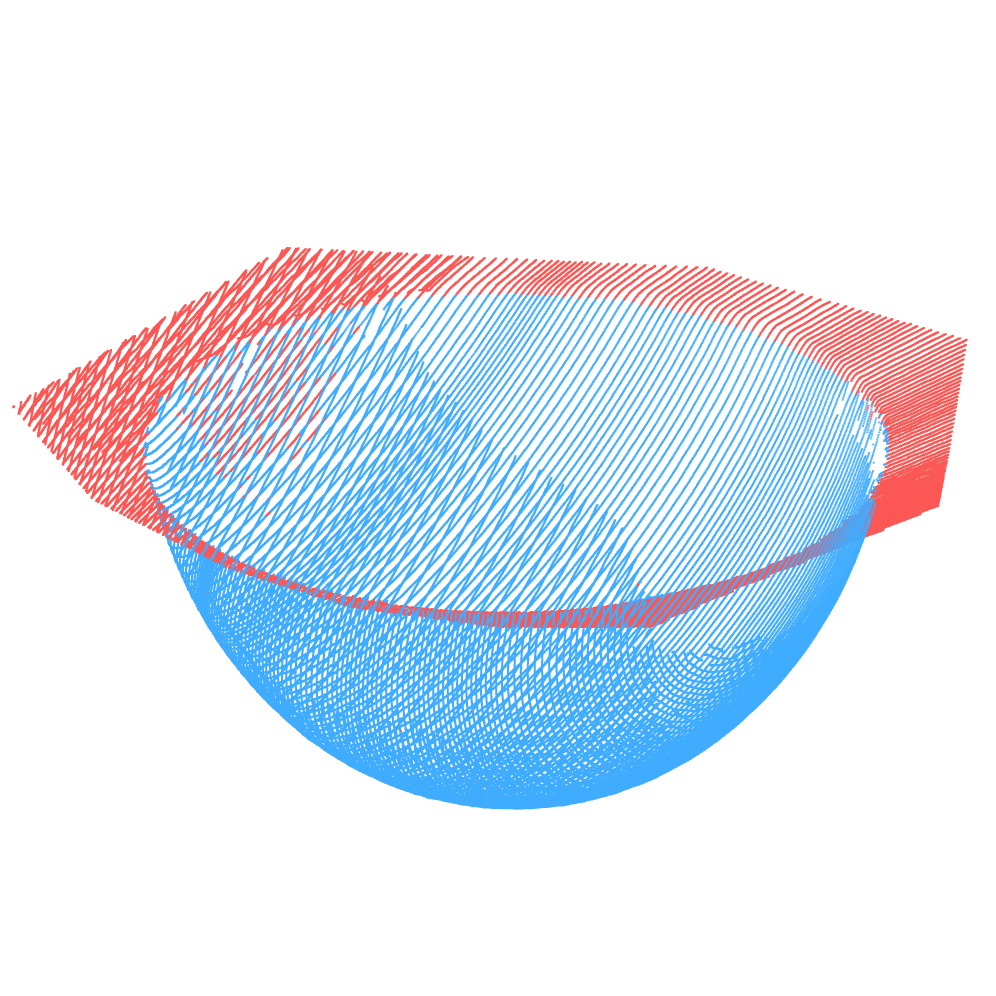

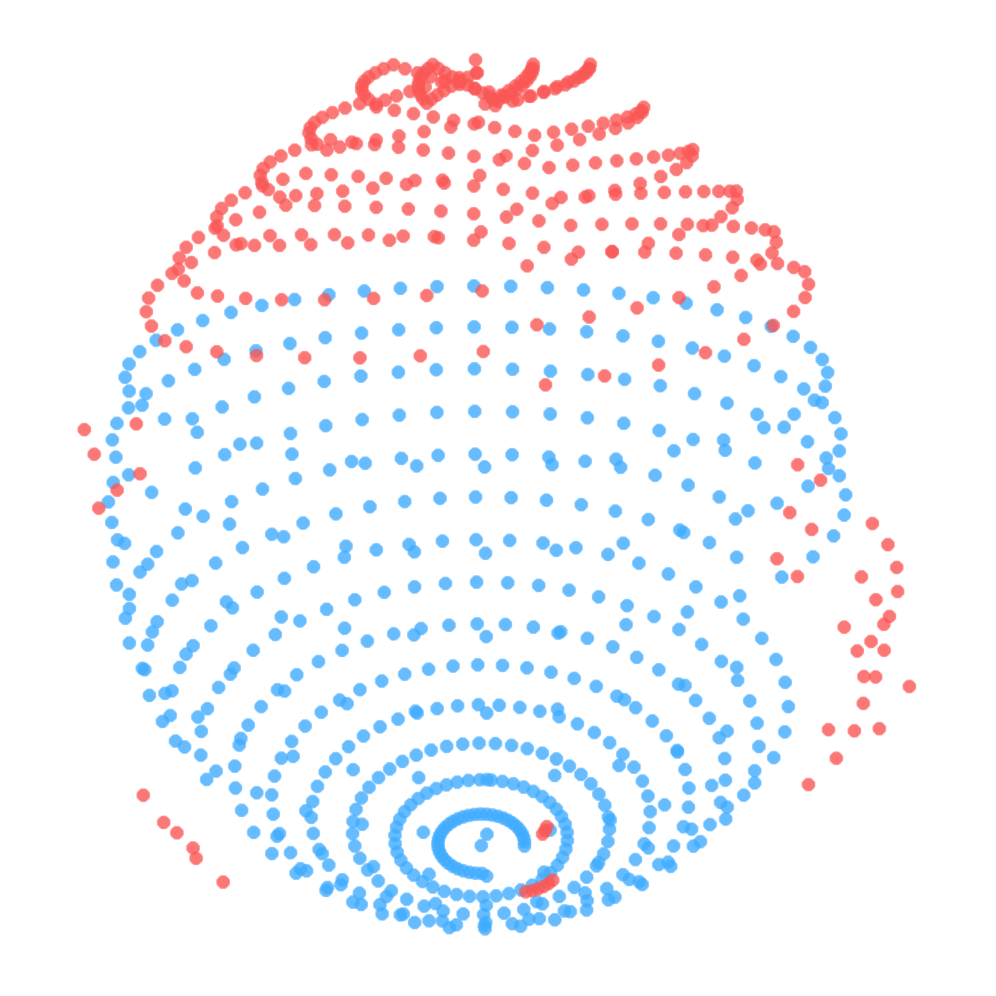

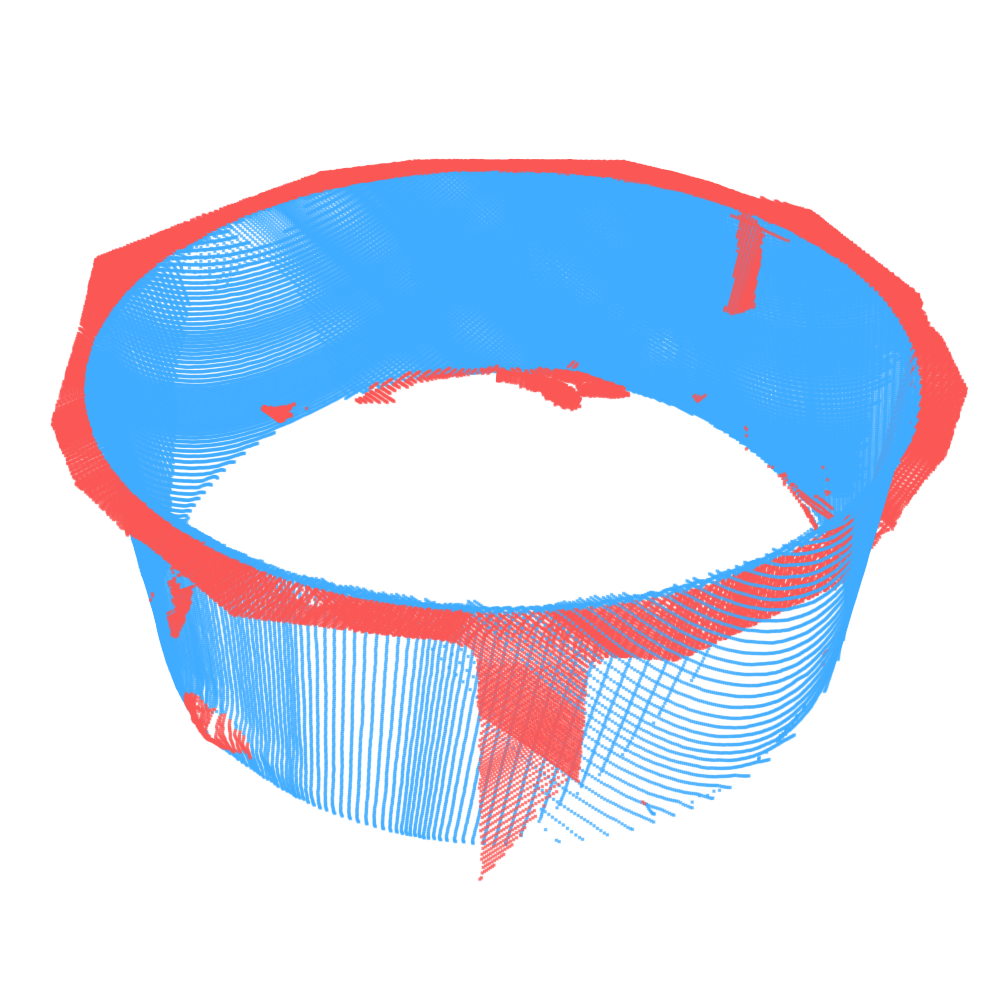

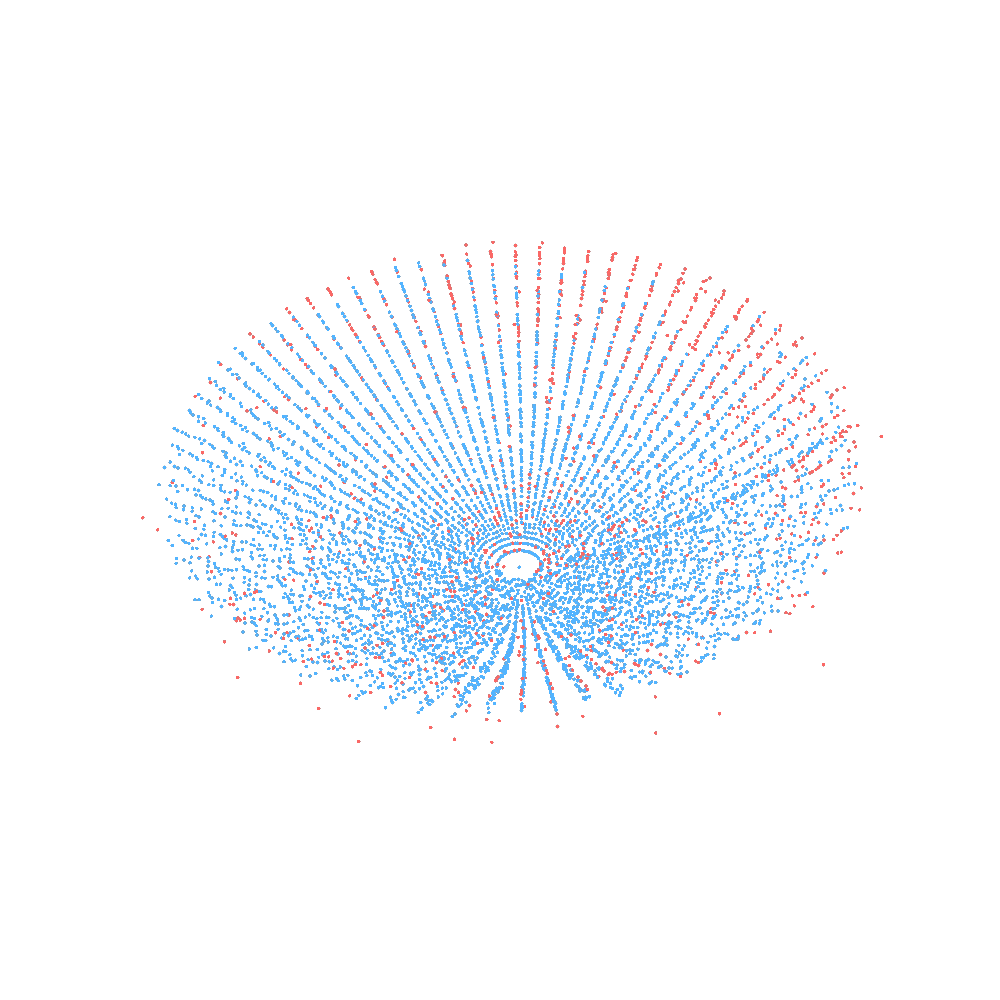

OI Core Technology automatically determines the quality/consistency of any data set and flags (but not discards) points that are outside of that range. No human interaction is required and numerically certain values are provided.

The final piece to controlling geometrical measurement data is to use InoraSRS. The SRS makes it possible to understand a measurement system’s capability and isolate that influence.

Our

Solution

Customer Benefits

By implementing OI powered geometrical modules in an existing software package or process, the results will move from numerically uncertain to certain. The absolute indications of quality given will save time that is wasted by the false positives and false negatives of uncertain results and trying to root cause issues that may not have actually existed in the first place.

Available Modules

These OI Powered Modules Are Currently Ready To Be Licensed For Commercial Use

Straight Line

Also Known As Orthogonal Regression

2-Dimensional

3-Dimensional

Plane

Plane In Arbitrary Spatial Location

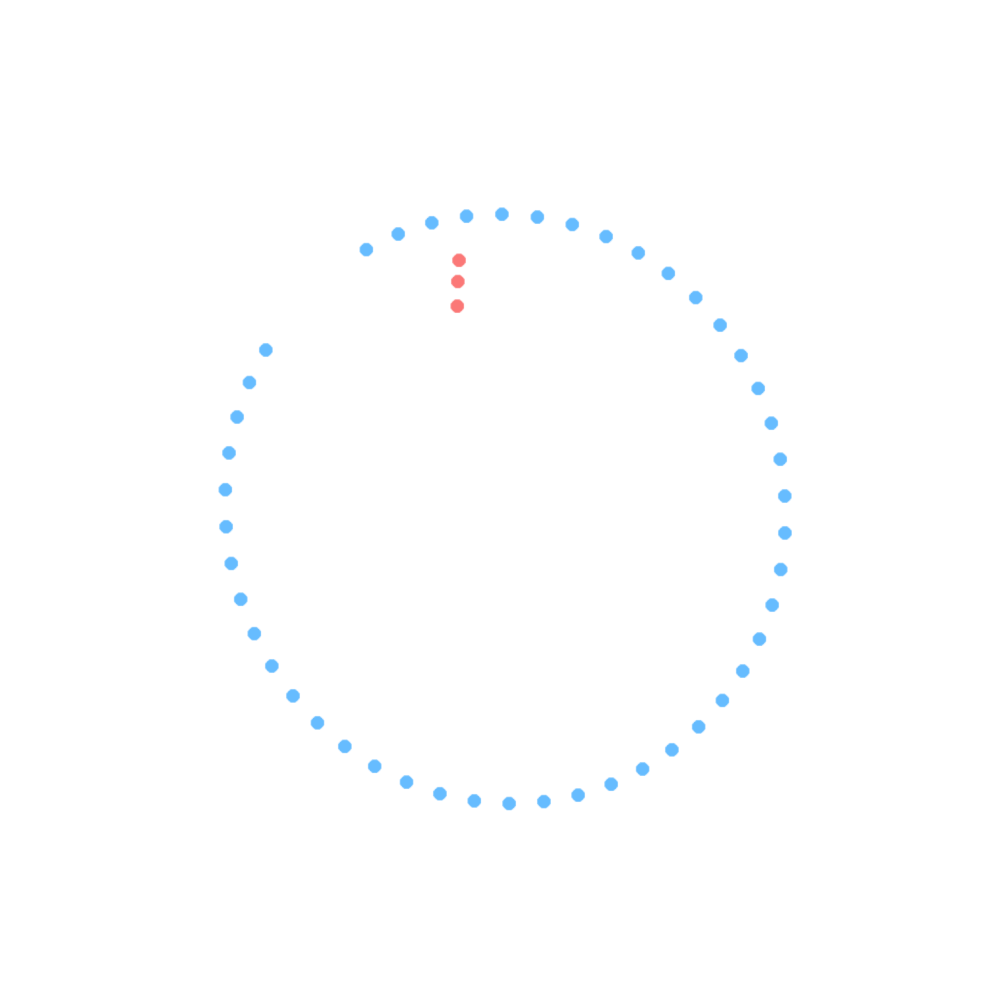

Circle

Circle In Arbitrary Plane Location

Circle In Arbitrary Spatial Location

Ellipse

Ellipse In Normal Plane Orientation

Ellipse In Arbitrary Plane Location

Ellipse In Arbitrary Spatial Location

Sphere

Sphere In Arbitrary Spatial Location

Ellipsoid

Ellipsoid In Arbitrary Spatial Location

Cylinder

Circular Cylinder In Arbitrary Spatial Location

Elliptical Cylinder In Arbitrary Spatial Location

Parabaloid

Circular Paraboloid

Elliptical Paraboloid

Cone

Circular Cone

Elliptical Cone

Hyperboloid

Circular Hyperboloid (1-Sheet, 2-Sheet)

Elliptical Hyperboloid (1-Sheet, 2-Sheet)

Polynomials

Linear Regression (Up To 10th Degree)

Autonomous Determination Of Polynomial Degree

Deformation Analysis

2-Dimensional

3-Dimensional

Network Adjustment

1-Dimensional: Vertical Networks

2-Dimensional: Plane Networks

3-Dimensional: Spatial Networks

Total Station Check

Verification and Calibration of Total Station / Laser Tracker

3-Dimensional Spatial Scanner (Similar Total Station)

2-D Transformations

Coordinate Transformations For:

4-Parameter (Similarity/Helmert)

6-Parameter (Affine)

3-D Transformations

Coordinate Transformations For:

6-Parameter (Similarity)

7-Parameter (Similarity)

9-Parameter (Affine)

10-Parameter (Robotic)

12-Parameter (Affine)

n-D Transformations

Coordinate Transformation for:

n-Parameter (Affine)